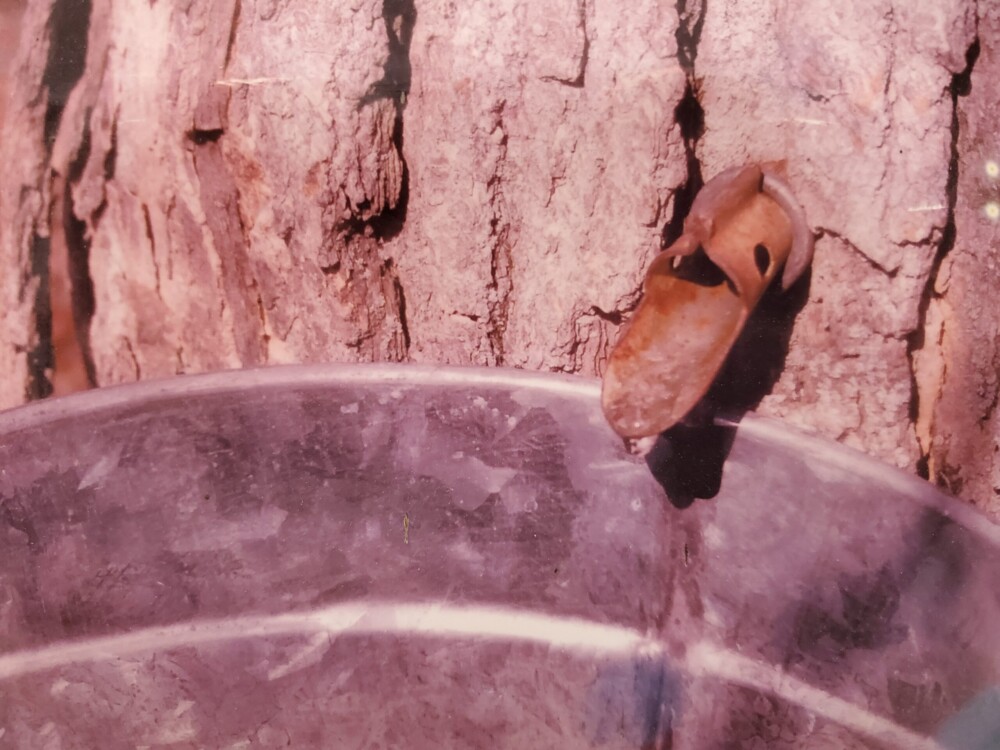

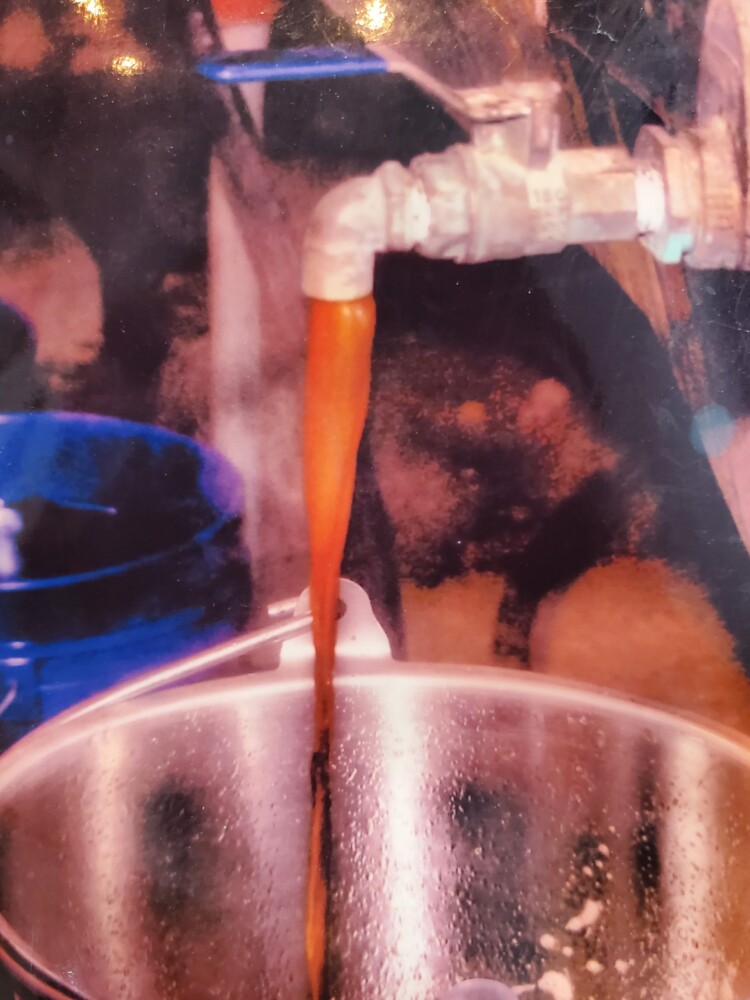

Sap is collected from sugar Maple trees, run through a process of reverse osmosis to remove some water in order to concentrate the sap. Then the sap is run through an old fashioned woodfire evaporator.

The sap is then boiled and continually processed until it reaches a consistency of 67% sugar. At that point, the hot syrup is filtered to remove any minerals contained in the hot syrup. Once that is finished, the syrup is ready to be bottled.

The sap is 2% sugar as it comes out of the tree. It takes approximately 40 gallons of sap to create 1 gallon of pure maple syrup.